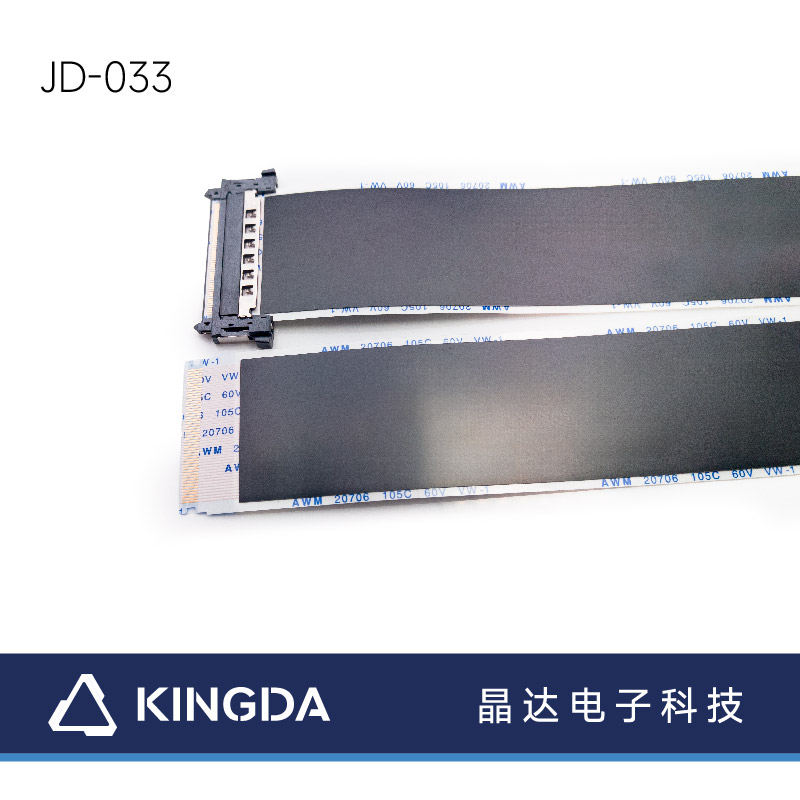

Lcd screen flex cable lvds ffc Flexible Flat Cable fi-re 0.5mm Pitch 51pin ffc screen cable 31-51Pin awm 20706 105c 60v vw-1

Applications:

The FPC cable widely used in COMPUTER, Consumer Electronics

● INTERFACE

FPC cable used for signal transimission and iternal layout in fields of diplay, flat television set, printer, scanner, computer digital camera, video camera, fax machine and copier, Agilent tester etc

● SUPPER FLEXIBLE & SOFT:

The cable is made of special materials and professional manufacturing process.Wire is very soft and flexible so that can be easily rolled up and unrolled.

Product Detail Specifications

Physical CharacteristicsCable

Cable Length:

Color:

Connector Style: Product

Product Weight:

Wire Diameter:

Packaging Information Package

Quantity: 1Shipping (Package)

Weight:

Product Description

0.5/ 0.8/ 1.0/ 1.25/ 2.0/ 2.54mm Pitch FFC Flexible Flat Cable

Specifications

|

Item |

FFC Capability |

| Product types | Single layer, |

| Layer | 1 layer flex pcb, |

| Maximum finished board size | 250*5000mm |

| Board thickness | FFC,0.06-0.4mm; |

| Min. trace width & spacing | 0.045/0.045MM |

| Base material | PI, PET, Electrolytic Copper, Rolled Copper |

| Tolerance for finished product | ±0.05mm |

| thickness | 0.1~0.5mm |

| PTH Hole Dia.Tolerance(plated-through-hole) | ±0.05mm |

| Stiffener | FR4/PI/PET |

Advantages of FFC routing

The ffc cable panel is small in size and light in weight, and the ffc cable cable panel was originally designed to replace the larger cable harness wire. On current plug electronics assembly boards, ffc row wiring is usually the only solution to meet the miniaturization and mobility requirements. A ffc row line (sometimes called a flexible printing circuit) is an etched copper circuit or a printed polymer thick film circuit on the substrate of a polymer. For devices that are both thin and light, compact and complex, the design solutions include moving from single-sided conductive lines to complex multi-layer three-dimensional assembly. The total weight and volume of f f c wiring are reduced by 70% from conventional circular wire harness methods. The ffc wiring can also be increased to its strength by the use of reinforced material or lining plates to achieve additional mechanical stability. Main advantages of FFC are 1. The f f c row line can move, bend, and twist without damaging the wire, and can follow different shapes and special package sizes. The only limitation is the volume-space problem. Because it can withstand millions of dynamic bends, the ffc row wiring works well in internal connection systems with continuous or regular movement, becoming part of the final product functionality. 2. The f f c exhaust cable has excellent electrical performance, dielectric performance and heat resistance. 3. The f f c row line has higher assembly reliability and quality. The ffc wiring reduces the hardware required for the internal connection, such as the solder points, relay wires, bottom plate wiring and cables commonly used in traditional electronic packaging, enabling the ffc wiring can provide higher assembly reliability and quality.